Share:

Quote, Buy, Track!

We make it easy to get instant pricing and purchase your metal at the click of a button. Track your order progress, get notified when it ships, and follow your shipment online until it’s delivered. It’s that easy!

The term “dual certification” is primarily employed when certifying a material as meeting the specifications for two separate alloys.

The most common example of this type of “dual” certification is 304 and 304L (or 316 and 316L). Material melted to the lower carbon range and processed to maintain the minimum properties for the straight grade will qualify as both an “L” and a regular grade. This dual certification has been standard practice since AOD refinement eliminated the cost differential between regular and low-carbon versions. Into the mid-70s, there was a significant premium charge (as much as 10%) for 304L and 316L. It should be noted that dual certifying of this type is not permitted when it infringes on the principle of grade substitution. For example, 321 could meet 304’s chemical and mechanical property requirements. But since 321 has the intentional addition of another element (titanium), it cannot be certified as 304.

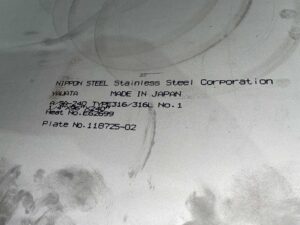

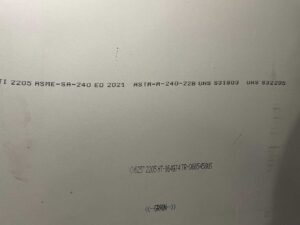

It is common to see 2205 dual certified as both UNS S31803 and UNS S32205. The original broad chemistry limits for S31803 permitted a composition that could result in poor mechanical and corrosion properties. The S32205 chemistry limits fall within the original ranges but are restricted to ensure better properties. The S32205 material also has a slightly higher minimum tensile. Dual certification was necessary, partly because until recently, only the S31803 alloy was included in the ASME BPVC.

We also see requests to dual-certify plate to a bar specification. It is not possible to certify plate as bar, except when specifically permitted by the specification. ASTM A484 covering stainless bar allows for the conversion of plate to flat bar. Except for ASTM B446 for 625, there is no such allowance for nickel alloy bars, although the differences between plate and bar product properties are minimal in many cases. AMS specifications for titanium bar products specifically prohibit the use of plate to produce bar. In addition, many (but not all) specifications define bar as being made in widths under 10″, while plate is produced as a product greater than 10″ wide. In any event, the applicable tolerances alone would generally prevent plate from being fully certified as bar since bar dimensional tolerances are much tighter than those for plate. However, when a customer’s requirement permits, it is possible to certify the chemical and mechanical properties of a plate to that of a corresponding bar specification. This often alleviates availability or minimum quantity issues associated with flat bar requirements for nickel alloys.

Another form of “dual certification” is called “multiple certification”. The most common situation for nearly all materials we supply is to certify them to an ASTM and an ASME material specification. This is possible because, in most instances, the ASME version is nearly identical, word for word, to the ASTM version. Another form of this multiple certification is certifying the material to an AMS specification. For most of the materials we supply, the requirements (chemical, mechanical, method of manufacture, finish condition, and tolerances) are the same (or similar enough) that the material can be produced to satisfy all the ASTM and AMS specifications requirements.

Please contact the Rolled Alloys Metallurgical Services group at 1-800-521-0332 or submit your questions below.

Buy Online Anytime

Our dashboard makes it even easier to shop online anytime from anywhere. Quote, buy, and track 24 hours a day.

Chicago Oktobarfest 2024

Join us for food, demo’s and prizes on October 11th from 11 a.m to 3:30 p.m at 711 Phoenix Lake Ave, Streamwood, Illinois.

High Temperature Strength – An Explanation of Creep and Rupture

High Temperature Strength – An Explanation of Creep and Rupture Back To All Articles Share: More Articles Quote, Buy, Track! We make it easy to

Positive Material Identification (PMI)

Positive Material Identification (PMI) Back To All Articles Share: More Articles Quote, Buy, Track! We make it easy to get instant pricing and purchase your

The History and Uses of AL-6XN®

The History and Uses of AL-6XN® Back To All Articles Share: More Articles Quote, Buy, Track! We make it easy to get instant pricing and

Bar Products: Specifications, Key Processes, and Common Confusions Explained

Bar Products: Specifications, Key Processes, and Common Confusions Explained Back To All Articles Share: More Articles Quote, Buy, Track! We make it easy to get

Chloride Stress Corrosion Cracking (CSCC) in Indoor Swimming Pools

Explore the causes and solutions for chloride stress corrosion cracking (CSCC) in 300 series stainless steels used in indoor swimming pool environments.